About ISM

Program

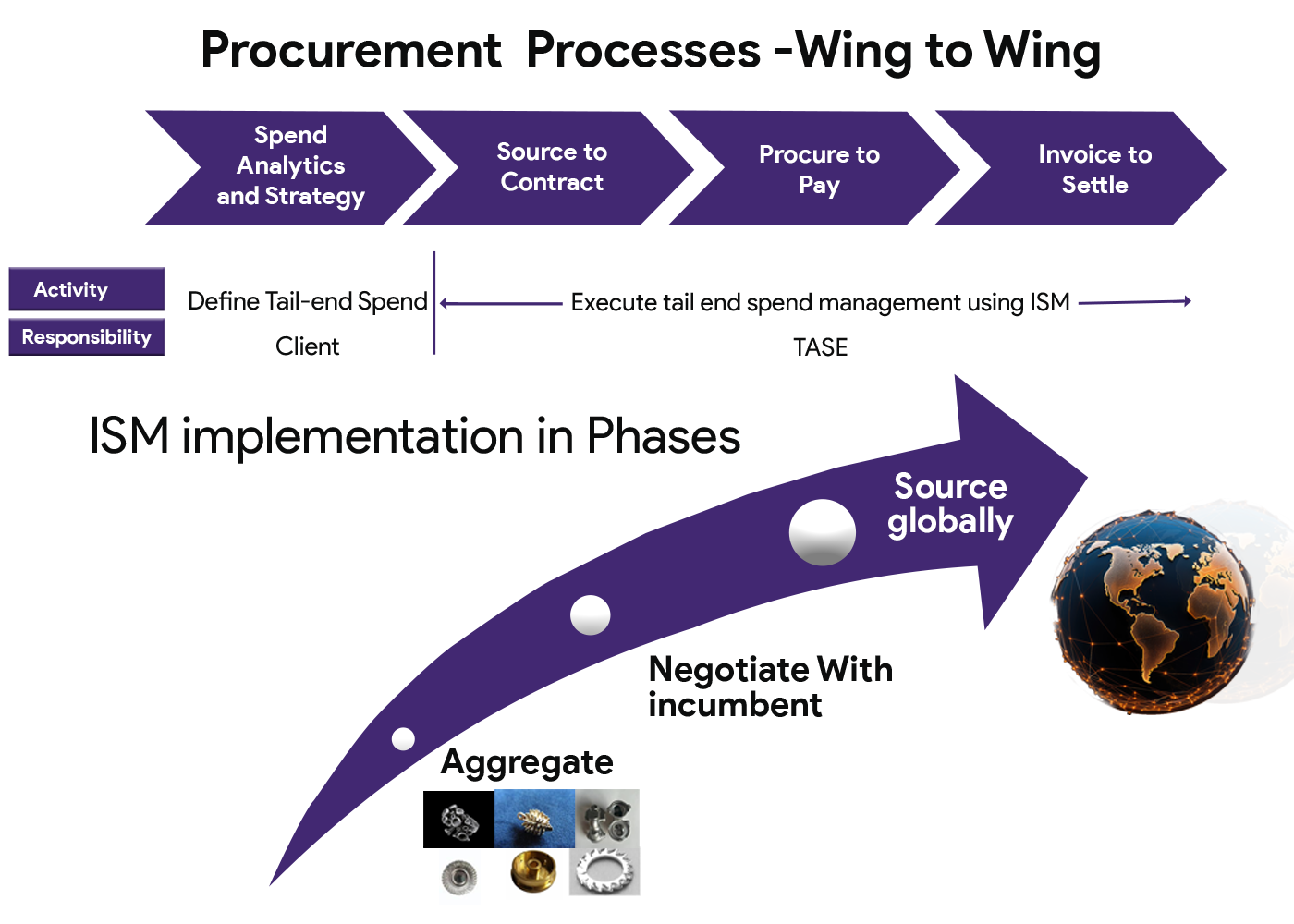

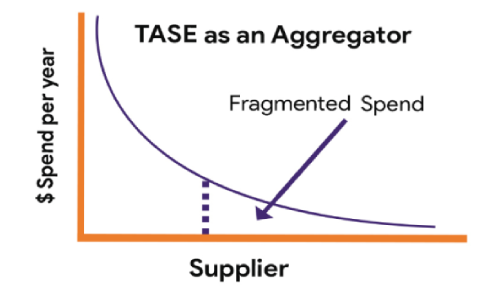

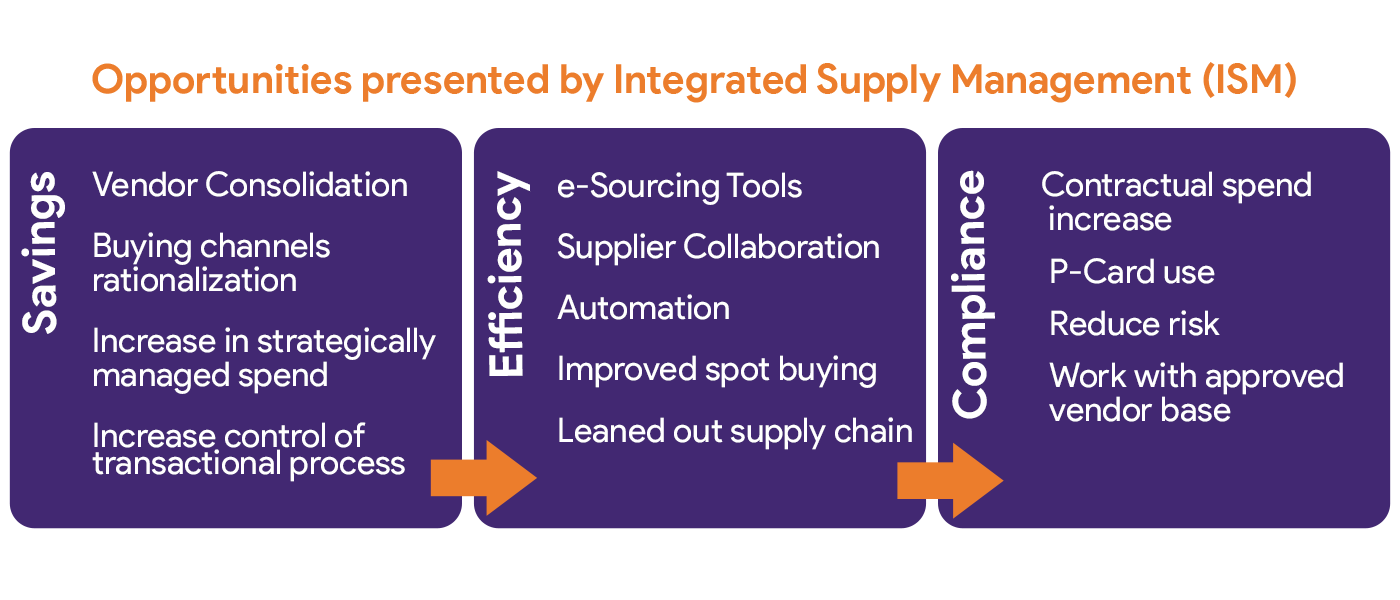

Integrated Supply Management - the ecosystem of people, process and technology which drive efficiency and effectiveness in non-core and tail end spend with suppliers.

Goal

Client benefit (net savings) by partnering with TASE with the effective management of supply of non-strategic machined components to global facilities.

Category

Machined components and assemblies.

Why TASE

Domain expertize in category of machined components Supply chain technology using collaboration to drive costs of transactions

Effective negotiations- Operational details, should cost.

Effective negotiations- Operational details, should cost.